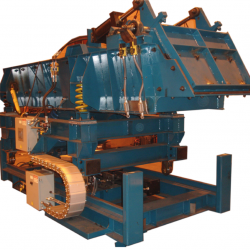

Cleaner Castings and reduced maintenance are just two of the advantages the patent pending DUCTA-CLEAN® Rotary Media Drum can offer. Media scrubs castings, removing sand, all while separating sprue and gates from castings. Media, tramp metal, and sand then exit the drum onto a GK vibratory sorting conveyor, which completely screens sand from the media, separates tramp metal, and then returns media back into the drum via the GK ROTOVEYOR™ rotary return conveyor.

DUCTA-CLEAN Rotary Media Drum

FEATURES:

- Separation of sand, media, and tramp metal is done outside the rotating assembly on a GK vibratory processor, eliminating rotating mass and wear to the drum body.

- GK fabricated liners are easier and safer to replace, and cost up to 75% less than cast grid systems.

- Patent-pending liner system eliminates compression rings, heavy cast liners, and excessive maintenance costs.

- Drum shell is not a wear item, saving you considerable maintenance funds and headaches.

- Drums use easy to source commercially available components.

- Available in standard and custom sizes to match your process design and throughput.