Technical Data

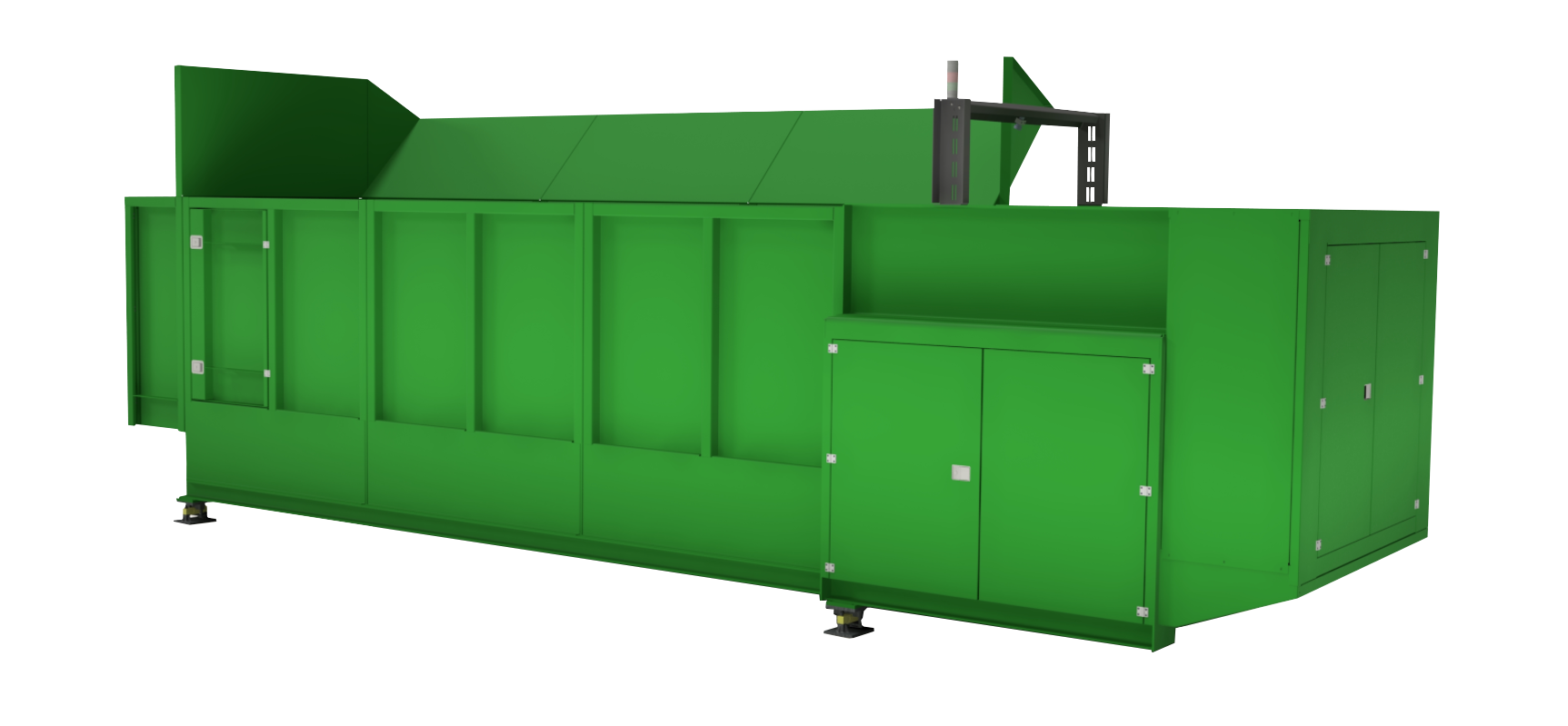

The material is loaded into the feeding hopper of the machine via an

upstream conveyor belt. A sensor monitors the fill level. To control the

feeding of the machine, the fill level is reported to the higher-level

control.

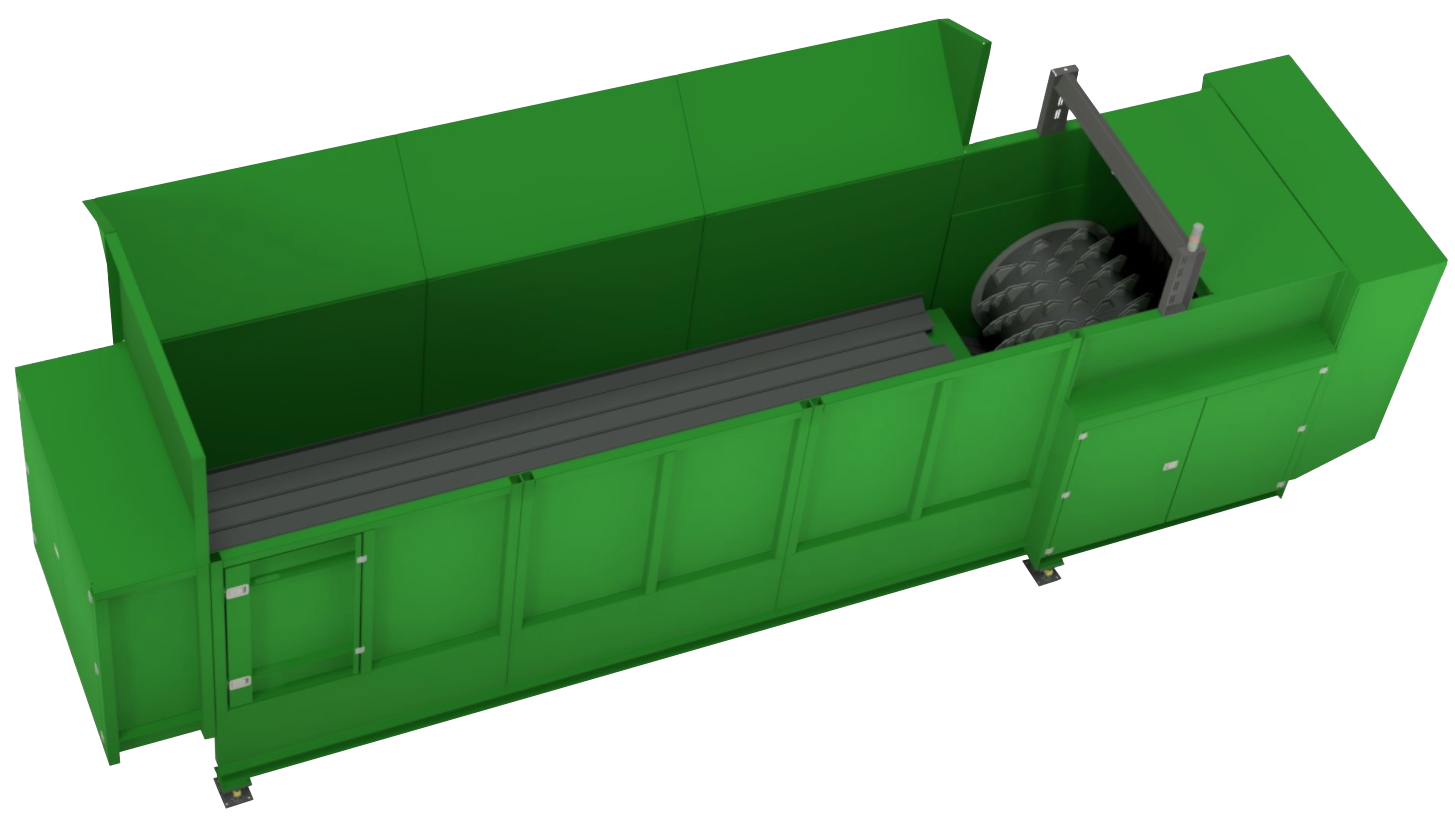

The bags are drawn in by the opening unit and opened and emptied

between the teeth of the drum and the hydraulically pretensioned

combs.

The material mixture drops out under the machine and falls to the

arranged conveyor belt below.

Impurities are drawn in and pressed against the combs by the rotary

movement of the drum. If the preload force is exceeded, one or more

segments open. The impurities can escape and the combs go back to the

starting position.

| CANYON | B1 |

| Variants | A / B / C |

| Throughput (m3/h) | up to 250* |

| Throughput (t/h) | up to 60* |

| Useful Width (m) | 1.7 |

| Drum variants | Single drum (A) / Double-Segment-Drum (B) / Multi-Segment-Drum (C) |

| Teeth | Standard: Welded, Optional: Screwed, Interchangeable Segment |

| Drive | Electro-Hydraulic |

| Drivepower (kW) | Control cabinet with PLC control included in basic machine |

| Revolution (1/min) | 15-45 |

| Control Cabinet (Control) | 5-35 |

| Fieldbus | Option: Profibus, EtherCAT, ModBus, CanOpen |

| Diagnostic and operating data logging | Option: Database record, Web-App, Smartphone App |

| Teeth Variants | Standard: HB400, Optional: Tungsten Carbide Coating |

| Fill Level Monitoring | Included in Basic Machine |

| Steel Substructure | Optional |

| *Throughput can vary depending on the material, material properties, moisture and composition. All values are approximate. | |