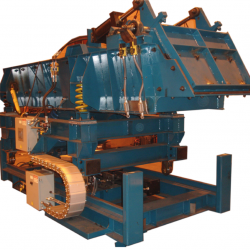

Proven in hundreds of applications worldwide, VIBRA-DRUM® Sand & Casting Conditioners have revolutionized high volume mold/sand handling for foundry applications. This versatile Two-Mass system gently tumbles castings and provides accelerated casting cooling through equalizing of sand/casting temperatures and evaporation of moisture. This tumbling action reduces sand lumps to original grain size and blends sand to equalize shakeout sand temperature — all in one continuous, energy-efficient operation.

The gentle tumbling action of the VIBRA-DRUM® keeps the castings in a bed of sand, never dropping or creating impact during the shakeout process. This action provides the gentlest shakeout in the industry, allowing the automated shakeout of fragile castings.

The Two-Mass VIBRA-DRUM® delivers continuous shakeout operation, plus superior material motion for efficient sand and casting processing. Natural frequency vibration produces a beneficial drum-like material rotation that quickly reduces sand lumps without casting damage. High-frequency agitation efficiently reduces sand to original grain size. Put it all together and you have a simple, easy-to-maintain, non-rotating design with all the environmental benefits of a totally enclosed drum — but with no air handling, sealing, or interface problems and no casting damage.