News & Events

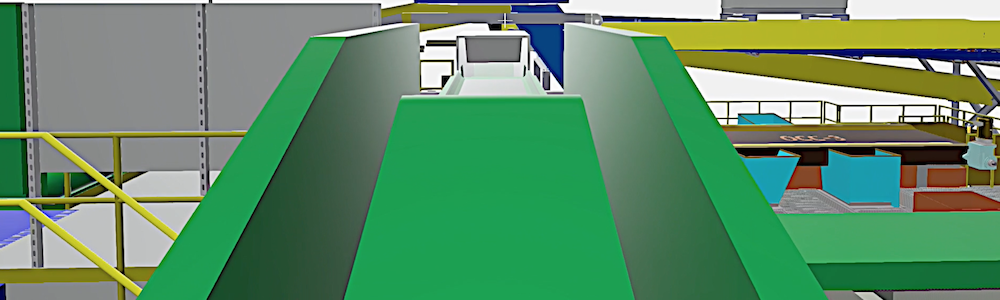

Palmer No-Bake Molding System at Southern Aluminum Foundry

In 2013, Southern Aluminum Foundry completed a $500,000 expansion to their No-Bake Process Line. This No-Bake Foundry system was sold to SAF, by MetalTech Systems. Thanks to Palmer Mfg and MetalTech Systems, SAF now has a No-Bake Capacity of 10,250 molds/year per shift. Known for years in the foundry industry, Palmer has developed the reputation …

Palmer No-Bake Molding System at Southern Aluminum Foundry Read More »

New MetalTech Systems Highlight Video

https://www.youtube.com/watch?v=Z2FbrVi47Dg

Single Stream Ballistic Separator to Marpan Recycling

MetalTech Systems of Pawleys Island, SC is proud to announce the sale of a new single stream Ballistic Separatorto Marpan Recycling of Tallahassee, FL www.marpan.com. Marpan recycling will soon be accepting single stream material from Tallahassee, FL and in order to meet the increased volume will be installing a new Ballistic Separator. The new ballistic …

Single Stream Ballistic Separator to Marpan Recycling Read More »

MetalTech Systems – What we’ve been up to!

MetalTech Systems brings you a long awaited, and much need re-vamp in our online videos. We are starting things off with our first commercial for Fall 2015! Enjoy!

MetalTech Systems – Fall 2015 Commercial #1

MetalTech Systems brings you a long awaited, and much need re-vamp in our online videos. We are starting things off with our first commercial for Fall 2015! Enjoy!

Pellenc Selective Technologies – July 2015 Newsletter

North America Newsletter July 2015 Pellenc ST America installs 10 machines at PET recycling plant in N.C. Pellenc ST North America recently finished installation of 10 Mistral optical sorters for a double PET sorting line (11 tons per hour) in NC, to upgrade an existing facility. The facility produces recycled PET flake (RPET) from …

Pellenc Selective Technologies – July 2015 Newsletter Read More »

North Augusta MSW Conveyor Replacement

City of North Augusta Solid Waste Authority, MetalTech Systems and Andrews Metal Works Team Up for Critical Repairs Challenge: Remove existing (15’) fifteen foot tail section of conveyor, fabricate replacement using existing conveyor as a template and install all within 48 hour window.